AGV automatic navigation logistics car

【Product Features】:

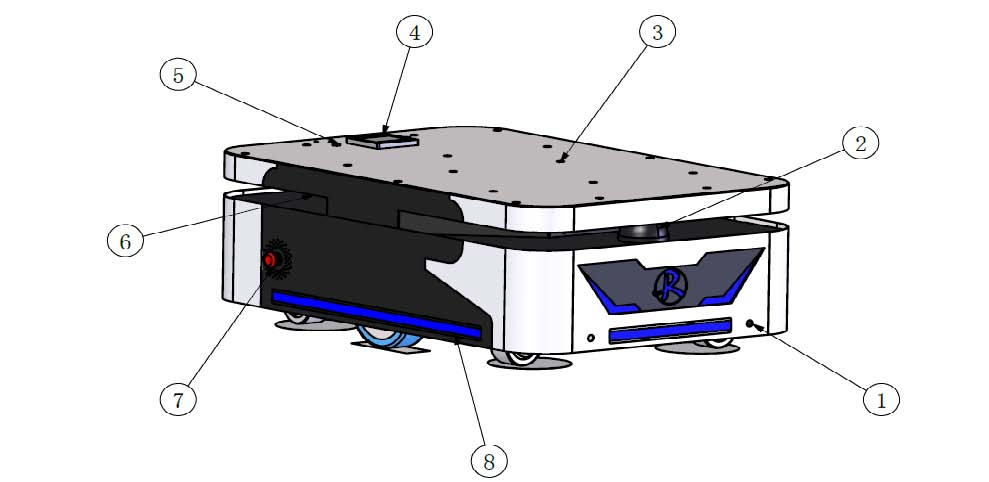

【Product Features】:Consisting of an independent AGV chassis, servo drive, and laser guidance module, it handles independent objects of the same or different phases based on object information.The system is compatible with the handling of paper, plastic boxes, bags, and bagged items. Full path self-learning, establishing a travel trajectory planning map, which can be self updated during the journey to avoid obstacles or find convenient ways。

Digital visualization operation and maintenance management, remote control, stability monitoring, and operational efficiency analysis

1. Speed: Based on conveying 250 kilograms and 1500 kilograms of materials, the maximum speed is 1.20 meters per second

2. Environment: No need to lay guide markers or guide rails.

3. Transportation capacity: Three levels, 60 kg, 250 kg, 1500 kg

4. Equipment accessories in the later stage: can be attached with rollers, conveyor belts, or shelves

5. Equipment operators: No need for manual intervention

6. Energy consumption: 2 KW

7. Safety system: International certified SICK or PILZ safety protection (interlocking, emergency braking, etc.) system

8. Intelligent components: Using 3D laser, sensing guidance or detection, servo controlled walking and driving systems as power sources and main control modules, and pneumatic and other forms of driving as auxiliary power sources

9. Background control: Start up, run control, adjustment, setting, fault alarm, troubleshooting, and data collection are achieved through the touch screen

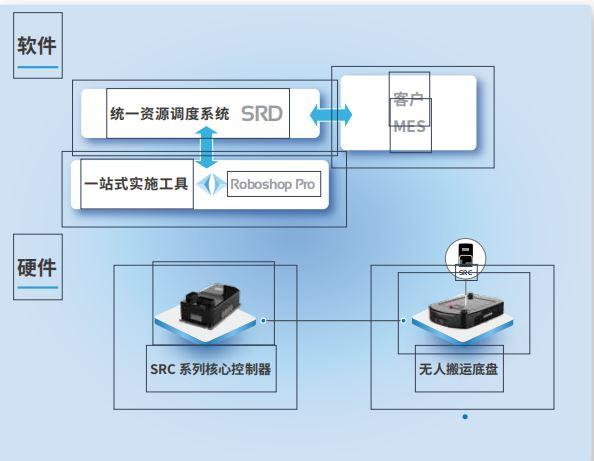

【Solution】:

By linking the loading and unloading truck delivery note, arrival note, WMS and ERP finished product transportation and product information, one touch screen can achieve automatic sorting, positioning, startup, loading and unloading truck functions. Provide cost-effective production methods and systems for logistics enterprises to achieve cost reduction and efficiency improvement. Suitable for the construction of intelligent logistics work surfaces in platforms, stations, distribution centers, and logistics distribution centers, as well as the renovation and upgrading of existing logistics production systems and optimization of factory MES systems。

By linking the loading and unloading truck delivery note, arrival note, WMS and ERP finished product transportation and product information, one touch screen can achieve automatic sorting, positioning, startup, loading and unloading truck functions. Provide cost-effective production methods and systems for logistics enterprises to achieve cost reduction and efficiency improvement. Suitable for the construction of intelligent logistics work surfaces in platforms, stations, distribution centers, and logistics distribution centers, as well as the renovation and upgrading of existing logistics production systems and optimization of factory MES systems。热线:

E-mail: