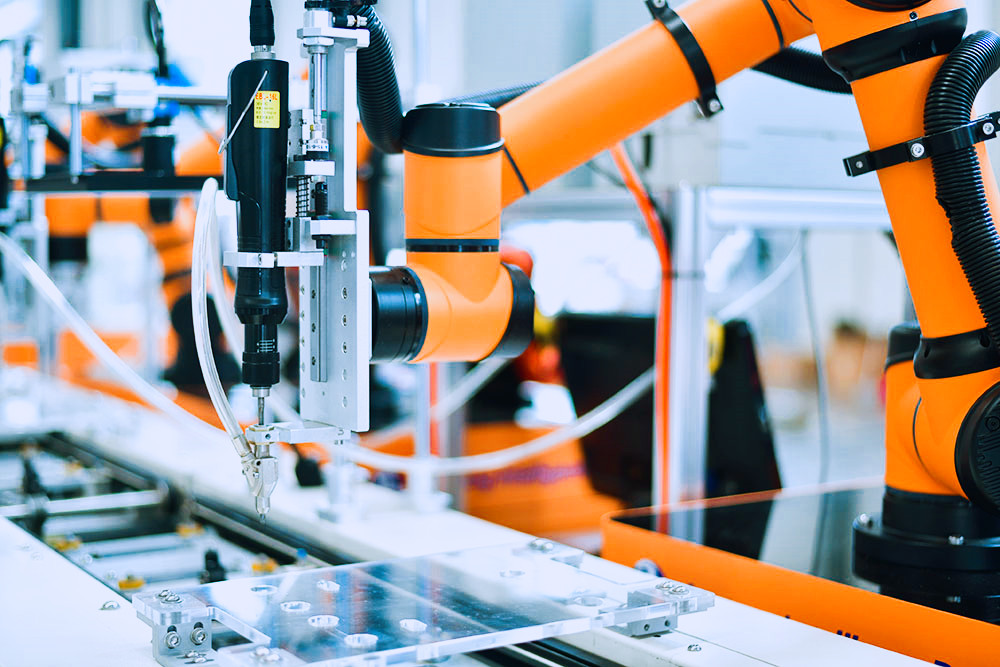

【Product Features 】:

Through the sorting and optimization of the robot body and peripheral material transportation functions, the robot standard workstation has achieved standardized, modular, and serialized standardized design and architecture, achieving a fast application mode of plug and play for the robot standard workstation. A single robot workstation is compatible with multiple product phases, and the same robot workstation can be extended and replicated. The software and hardware are generally compatible, suitable for the unmanned production needs of the 3C industry in processes such as cutting, screwing, coating, testing, labeling, and packaging. Industrial Internet interworking, 5G communication and real-time control cloud computing, monitoring, operation and maintenance, data automatic mining and analysis. Automatic monitoring of the entire production chain and automatic identification, alarm, and elimination of defective products.

【Standard robot workstation architecture】:

Robot general (six axis joint, SCARA, Cartesian coordinate system)

Multiple fixtures (three to four automatic replacements), multiple workstations

Linear servo transmission (GT coil, guide rail, and slider)

Installation positioning (600X600mm any direction)

No screw connection

Equipment operators: No need for manual intervention

Energy consumption: 0.2-2KW

Security system: internationally certified SICK/PILZ security protection (interlocking, emergency braking, etc.) system

Intelligent components: servo material grouping and sorting, multi joint robot and control system as power source and main control module, pneumatic and other forms of driving as auxiliary power source

Human machine interface: Implement operation control, adjustment, setting, fault alarm, troubleshooting, and data collection of robot workstations through touch screens

【Solution】:

Provide a new front-end automated delivery system based on intelligent manufacturing for enterprises, with unmanned warehousing, outbound, fully digital intelligent production system, production mode, and production services. Materials will automatically enter the robot workstation through WMS and MES systems. According to production dispatch orders and production processes, the robot workstation will perform unmanned processing, production, assembly, product testing, or packaging work after receiving work tasks. The intelligent management system for robot workstations can help production enterprises overcome the difficulties of high traditional production costs, incomplete digital functions, and an inability to guarantee the production workforce. By linking the intelligent production system of standard robot workstations with WMS and ERP for finished product transportation and product information, the intelligent production of standard robot workstations can be carried out in the entire production process with one touch screen or remote control, providing the most cost-effective production method and system for manufacturing enterprises to achieve cost reduction and efficiency increase. Suitable for the construction of new intelligent production bases or intelligent production working faces, the intelligent transformation and upgrading of existing production systems, and the optimization of MES systems in old factories.

热线:

E-mail: