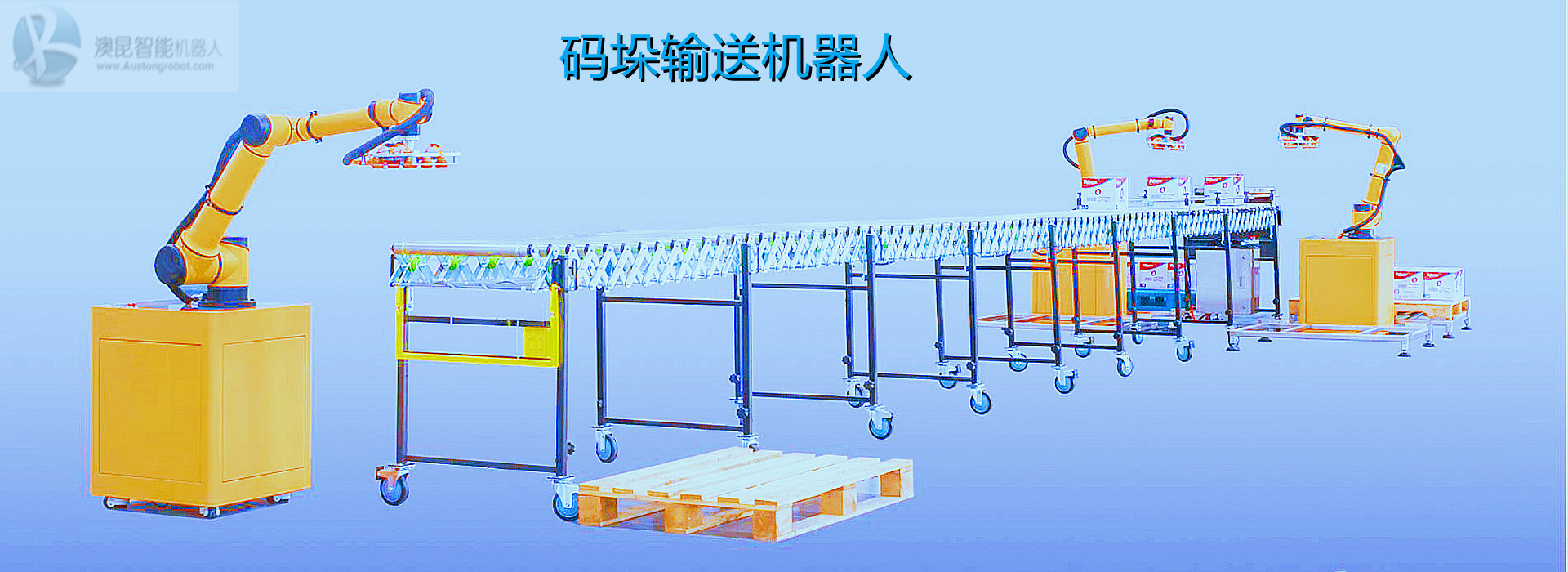

Logistics sorting, palletizing, and unpacking

【Product Features】:

Modular design, compact structure, easy operation, composed of multi joint or parallel parallel robots, servo drive modules, swing wheels, or high-speed endless push block conveyor chains, automatically conveying different product phases based on material information, and handling logistics materials such as warehousing, sorting, palletizing, and unpacking. The system is compatible with the processing of paper, plastic boxes, bags, and bagged goods, with fully automated information operation, online monitoring of the entire production chain, automatic identification and alarm of damaged, damaged, wrong, and wrong boxes, digital visual operation and maintenance management, and remote control, stability monitoring, and operational efficiency analysis

【Equipment parameters】:

Sorting: Based on conveying 5Kg, with a volume of 300 * 300 * 300 materials as the benchmark, the maximum sorting speed is 6000 pieces (boxes)/hour;

Stacking: single machine, 300+boxes/hour;

Discharging: 1500-2000 boxes/hour

2. Device compatibility

Sorting: 50+product phases/per line

Stacking: 4 phases/pallet

Discharging: 4 phases/pallet

Equipment operator: one

Energy consumption: 50 KW

Security system: internationally certified SICK/PILZ security protection (interlocking, emergency braking, etc.) system

Intelligent components: The visual+3D laser+sensing+fully intelligent grouping, sorting, distribution, and control system is used as the power source and main control module, and pneumatic and other forms of driving are used as auxiliary power sources

Human machine interface: Control, adjust, set, alarm, troubleshoot, and collect data for transportation, sorting, palletizing, and unpacking operations in the logistics production system through a touch screen

【 Solution】:

The material sorting, palletizing, and dismantling equipment of intelligent logistics systems can help logistics production enterprises overcome the difficulties of high logistics production costs, incomplete digital functions, and an inability to guarantee the production workforce.

Through the processing of incoming and outgoing materials, as well as WMS and ERP finished product transportation and product information linkage, the logistics transportation system can ensure the implementation of equipment functions such as automatic transportation, sorting, palletizing and dismantling, intact product detection, and temporary storage of materials through one touch screen throughout the entire production process.

Modular design, compact structure, easy operation, composed of multi joint or parallel parallel robots, servo drive modules, swing wheels, or high-speed endless push block conveyor chains, automatically conveying different product phases based on material information, and handling logistics materials such as warehousing, sorting, palletizing, and unpacking. The system is compatible with the processing of paper, plastic boxes, bags, and bagged goods, with fully automated information operation, online monitoring of the entire production chain, automatic identification and alarm of damaged, damaged, wrong, and wrong boxes, digital visual operation and maintenance management, and remote control, stability monitoring, and operational efficiency analysis

【Equipment parameters】:

Sorting: Based on conveying 5Kg, with a volume of 300 * 300 * 300 materials as the benchmark, the maximum sorting speed is 6000 pieces (boxes)/hour;

Stacking: single machine, 300+boxes/hour;

Discharging: 1500-2000 boxes/hour

2. Device compatibility

Sorting: 50+product phases/per line

Stacking: 4 phases/pallet

Discharging: 4 phases/pallet

Equipment operator: one

Energy consumption: 50 KW

Security system: internationally certified SICK/PILZ security protection (interlocking, emergency braking, etc.) system

Intelligent components: The visual+3D laser+sensing+fully intelligent grouping, sorting, distribution, and control system is used as the power source and main control module, and pneumatic and other forms of driving are used as auxiliary power sources

Human machine interface: Control, adjust, set, alarm, troubleshoot, and collect data for transportation, sorting, palletizing, and unpacking operations in the logistics production system through a touch screen

【 Solution】:

The material sorting, palletizing, and dismantling equipment of intelligent logistics systems can help logistics production enterprises overcome the difficulties of high logistics production costs, incomplete digital functions, and an inability to guarantee the production workforce.

Through the processing of incoming and outgoing materials, as well as WMS and ERP finished product transportation and product information linkage, the logistics transportation system can ensure the implementation of equipment functions such as automatic transportation, sorting, palletizing and dismantling, intact product detection, and temporary storage of materials through one touch screen throughout the entire production process.

热线:

E-mail: